Project Description

Aston University is an award-winning university located in Aston, Birmingham.

The university was founded in the 19th century when Birmingham and Midland Insitute created a School of Metallurgy. It became the Birmingham Municipal Technical School in 1895, and several other name changes before Aston gained university status in 1966.

Five schools make up the university: Engineering and Applied Science, Life and Health Sciences, Languages and Social Sciences, the Aston Medical School and the Aston Business School, with around 11,000 students combined.

Aston Business School is ranked in the Top Global 100 for Master’s in Business and Management and is triple accredited – a position held by only 1% of business schools worldwide.

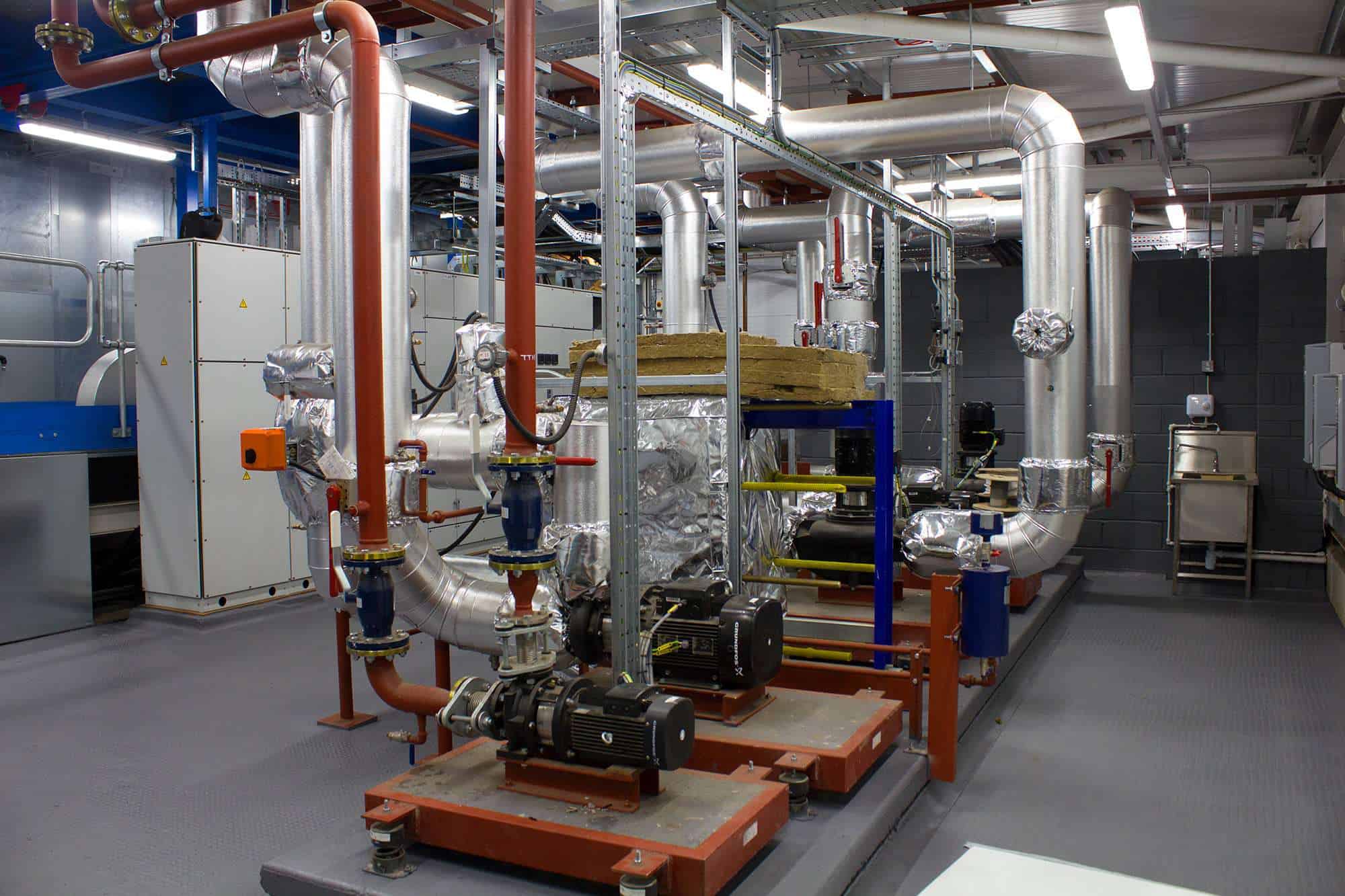

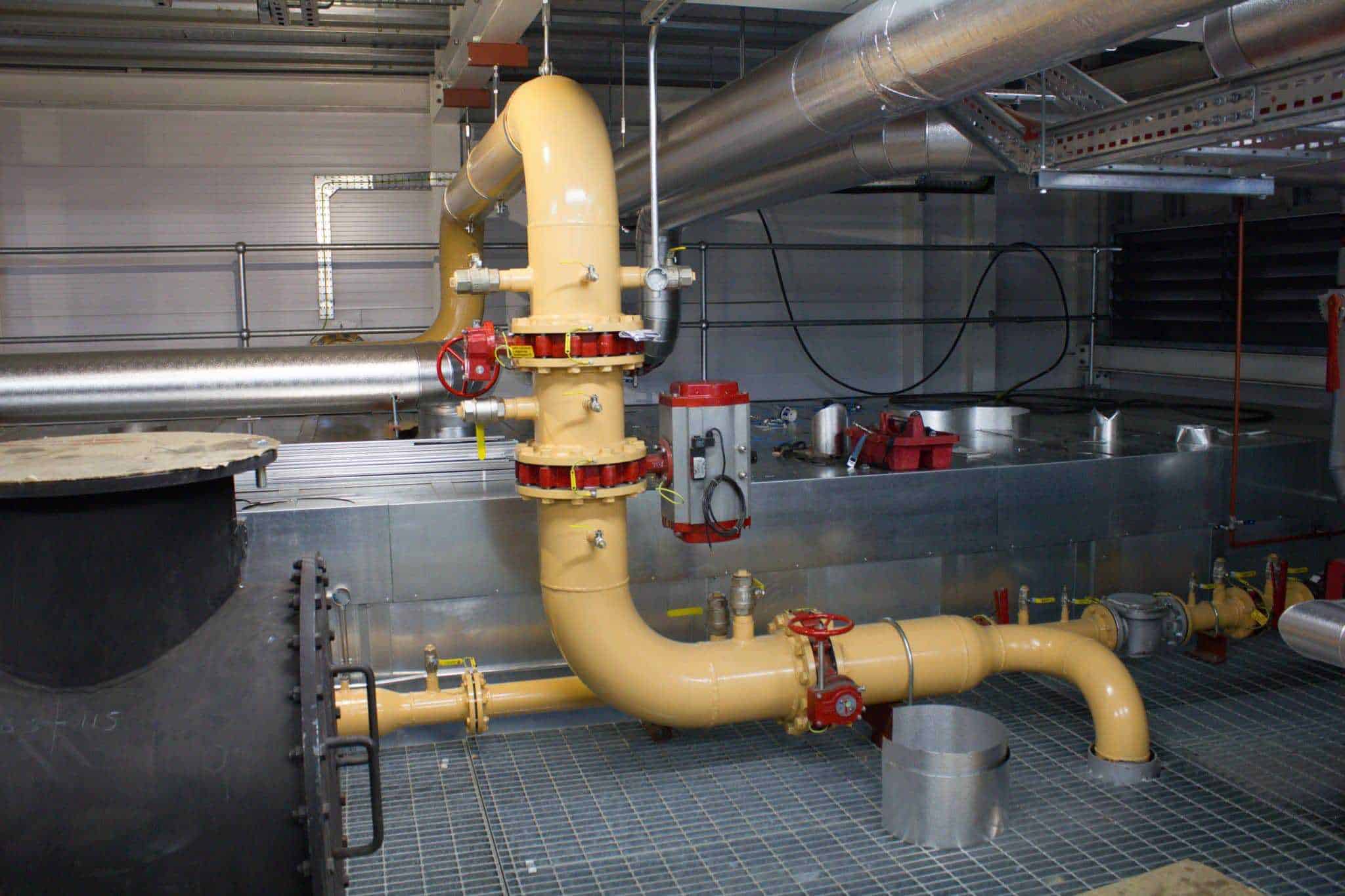

Due to joining the City’s District heating system, the university required a new spine of flow and return Pipework.

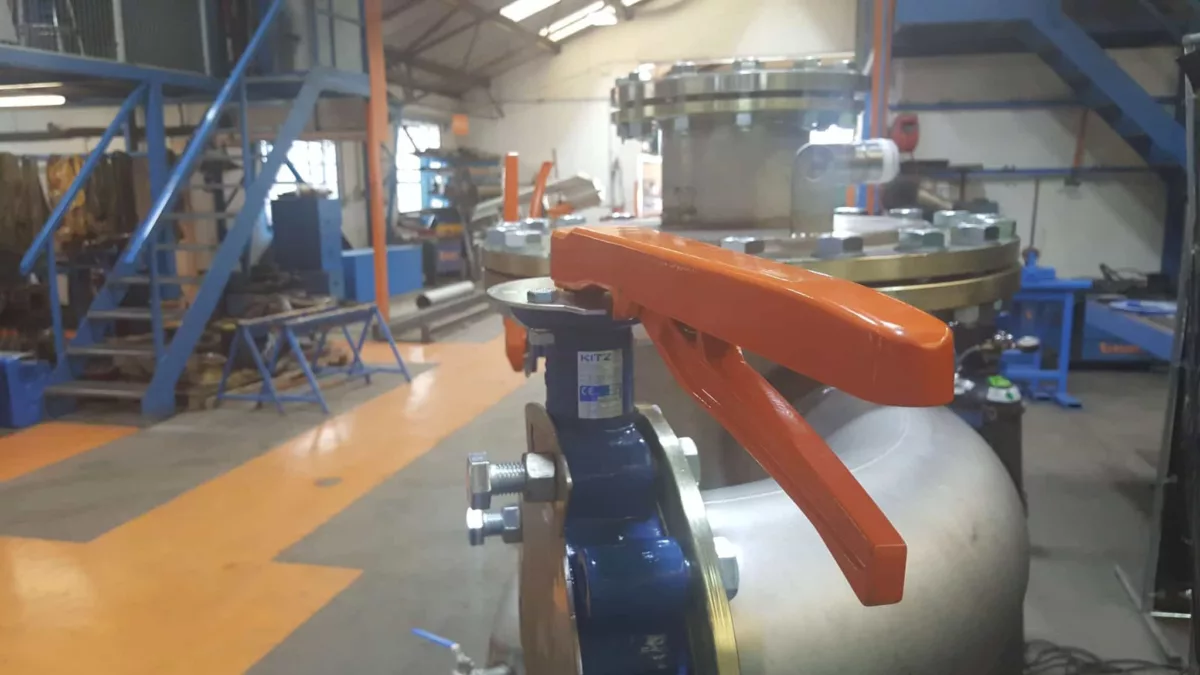

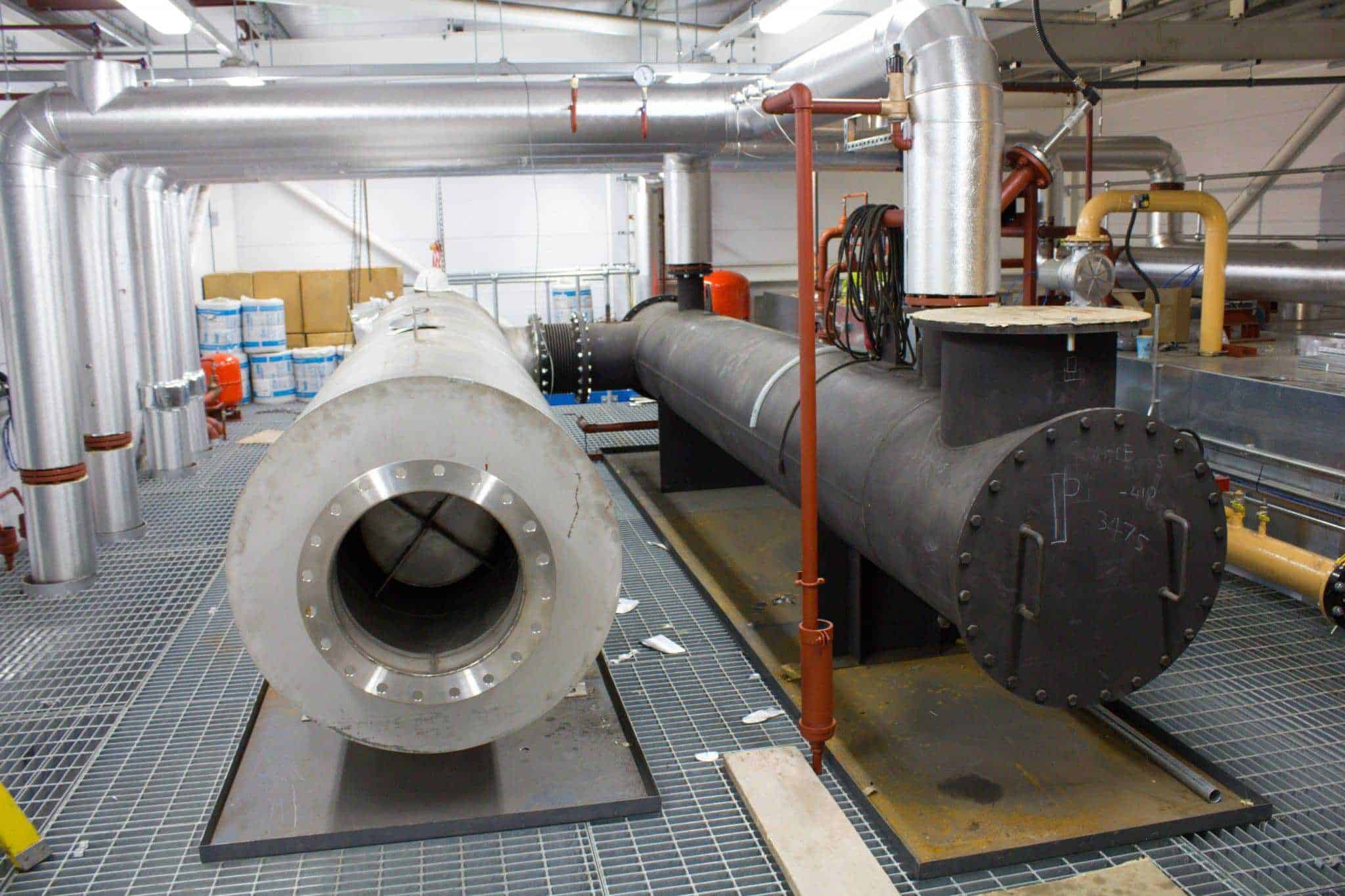

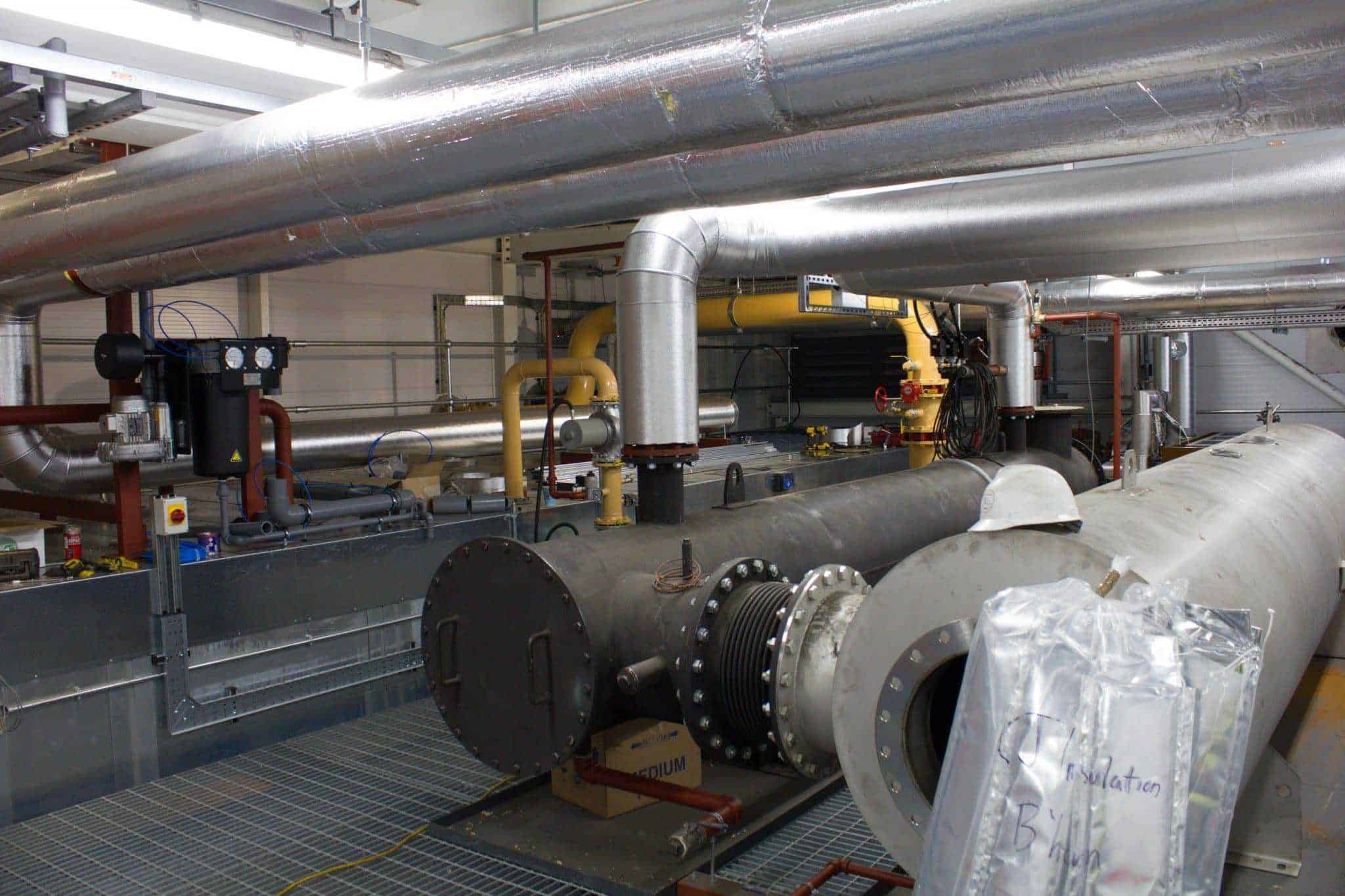

We needed to fabricate and install the constant temperature pipework for the district supply.

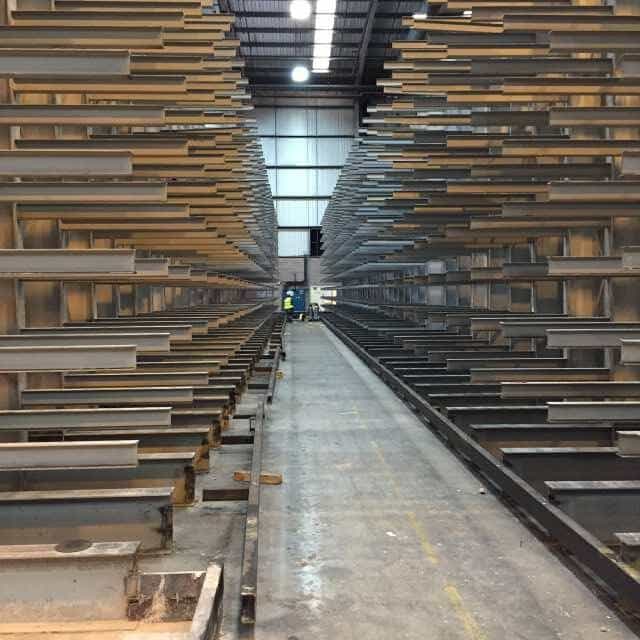

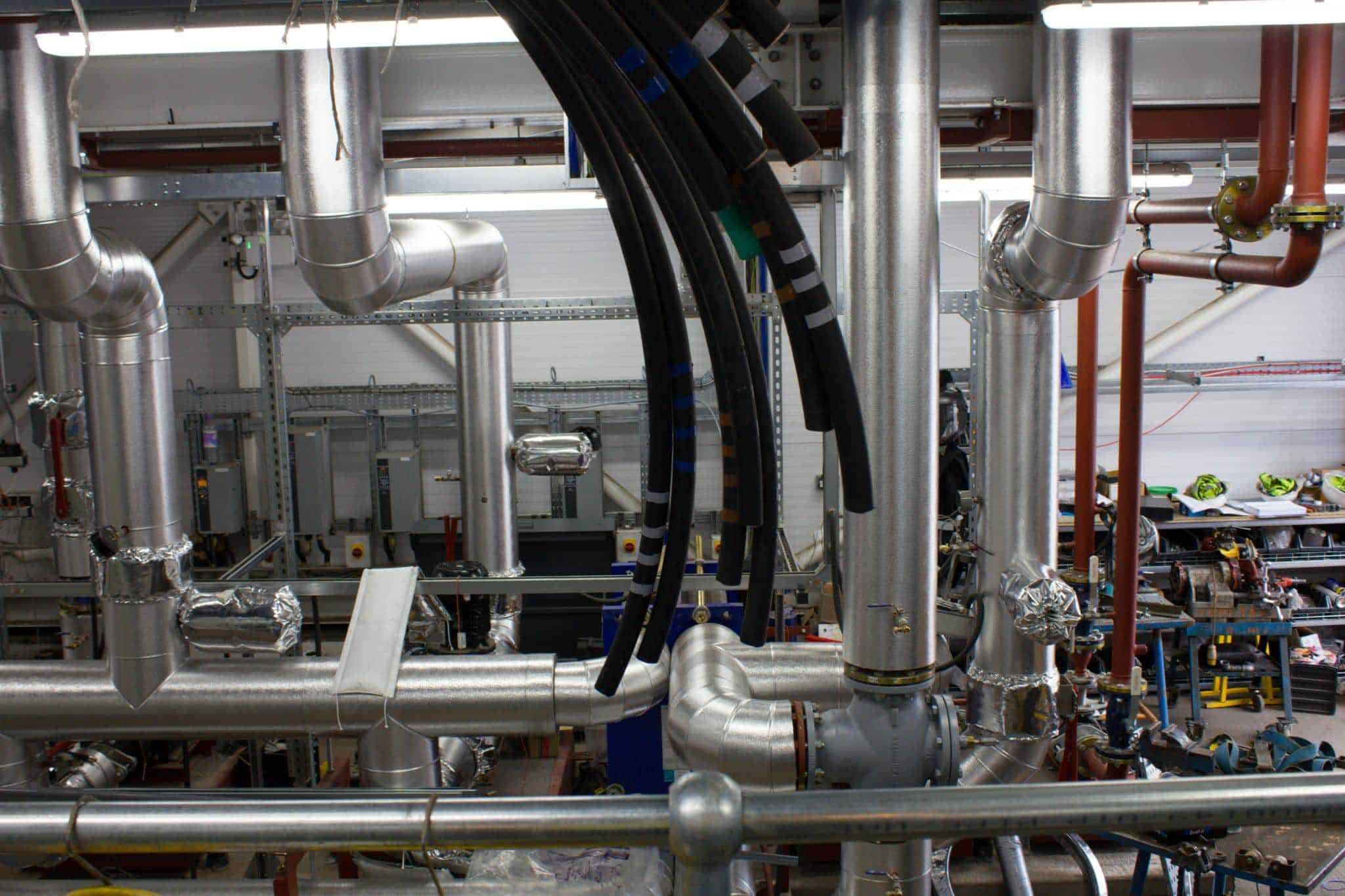

We pre-fabricated 200m of 8″ pipework back in our workshop. We do this to minimise on-site disruption.

Our transportation team then delivered the pipework to the site. Our pipefitters and coded welders were then able to start the installation.

Following the plans, we installed the Pipework over many levels of the main University building.

The new Pipework will feed two new plants in 2 more external university buildings. The district supply is part of an ongoing project.

Project Details

Project : Aston University District Pipework

Services Required: Pipework Fabrication, Coded Welding, Installation, Project Management

Customer: Aston University