Project Description

Varlowe was approached by Briggs & Forrester to provide a comprehensive solution for installing a fully welded stainless steel gas main at The Queen Elizabeth Hospital Birmingham.

With expertise in engineering, design, installation, and maintenance, Briggs & Forrester is a UK leader in building services engineering, prioritizing high quality and energy efficiency.

The Queen Elizabeth Hospital Birmingham, located in the Edgbaston area near the University of Birmingham, is a major hospital with 1,215 beds and a cost of £545m to construct. Named after Queen Elizabeth The Queen Mother, it provides a wide range of services to local and regional populations, including liver, heart, and lung transplantation, cancer studies, and a specialist centre for military personnel. The hospital has the largest solid organ transplantation programme in Europe and the largest renal transplant programme in the UK. It also features the world’s largest single-floor critical care unit, with 100 beds.

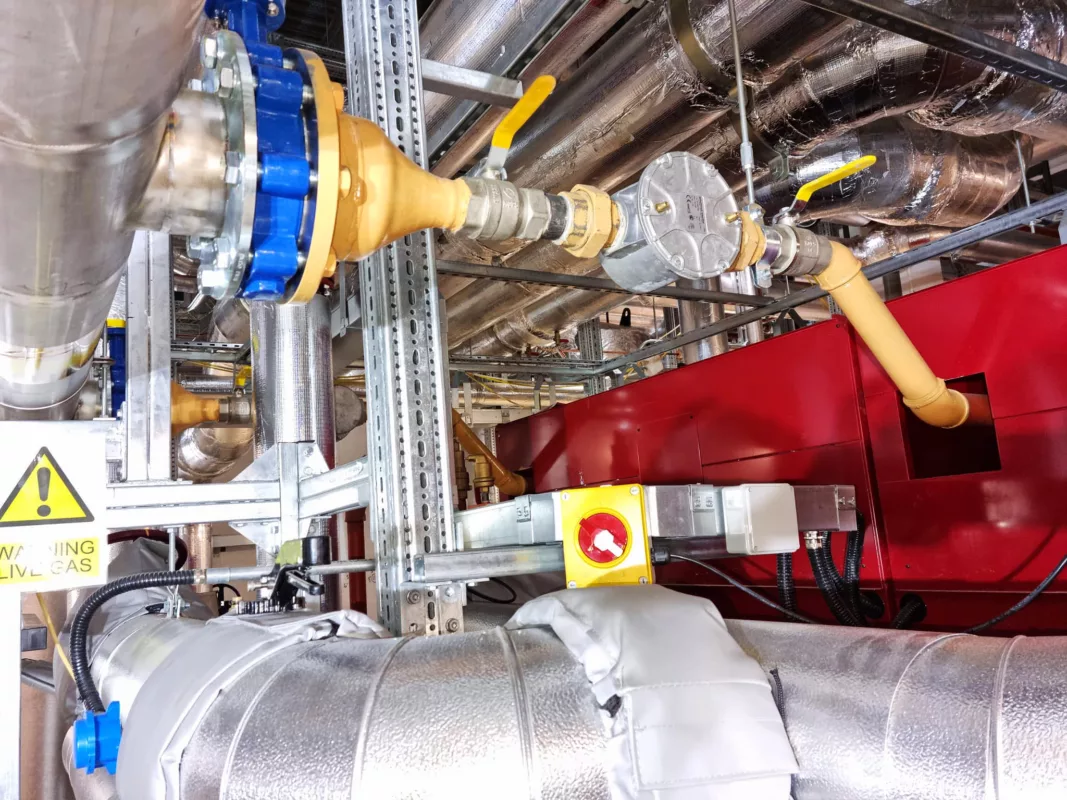

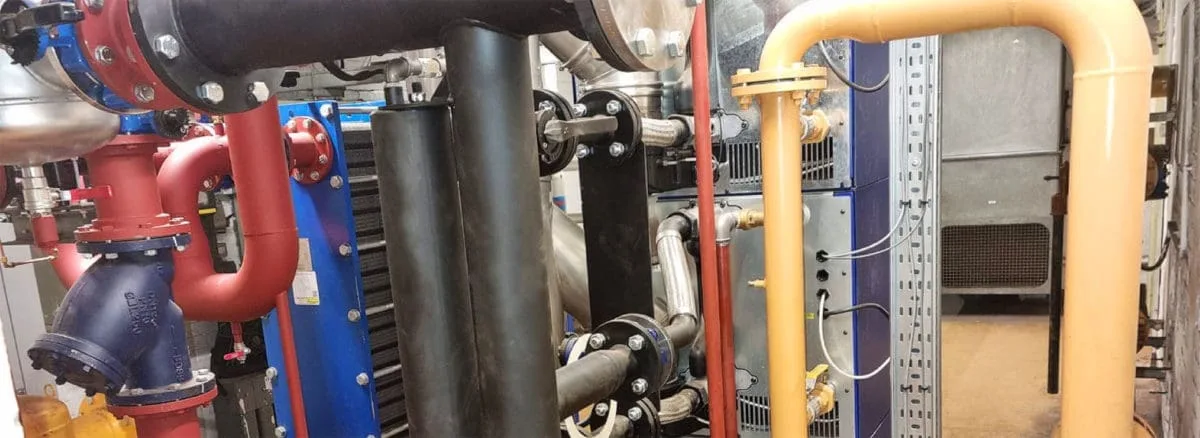

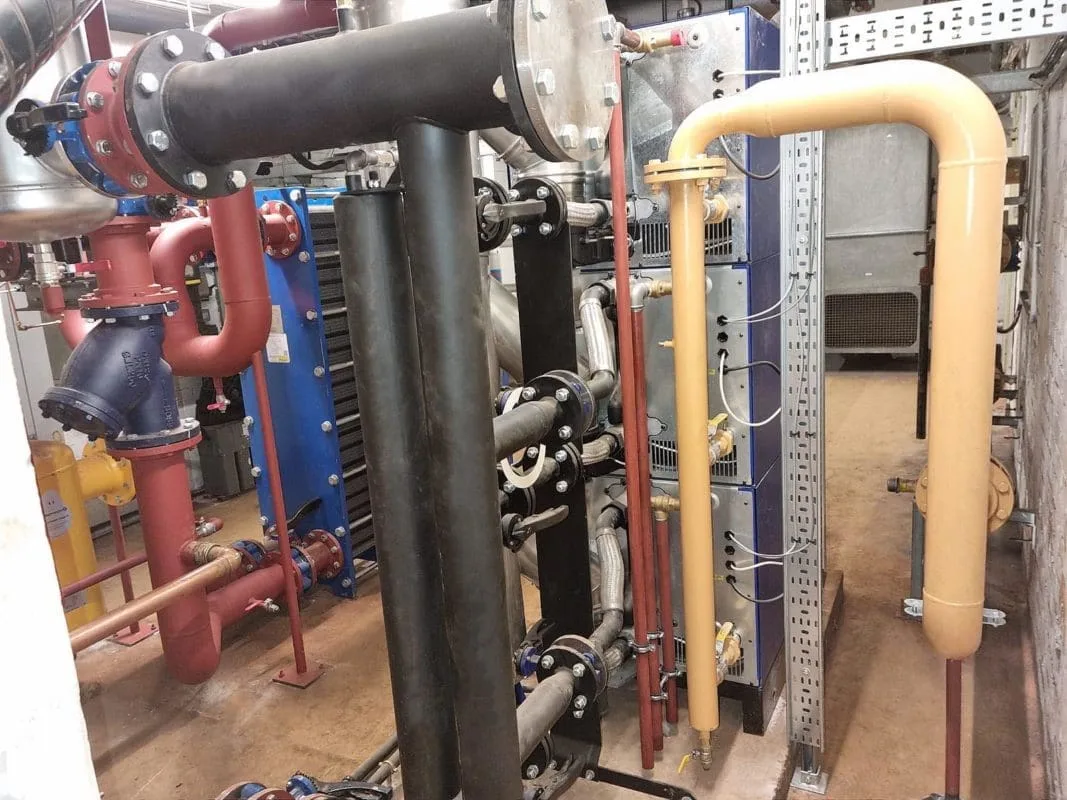

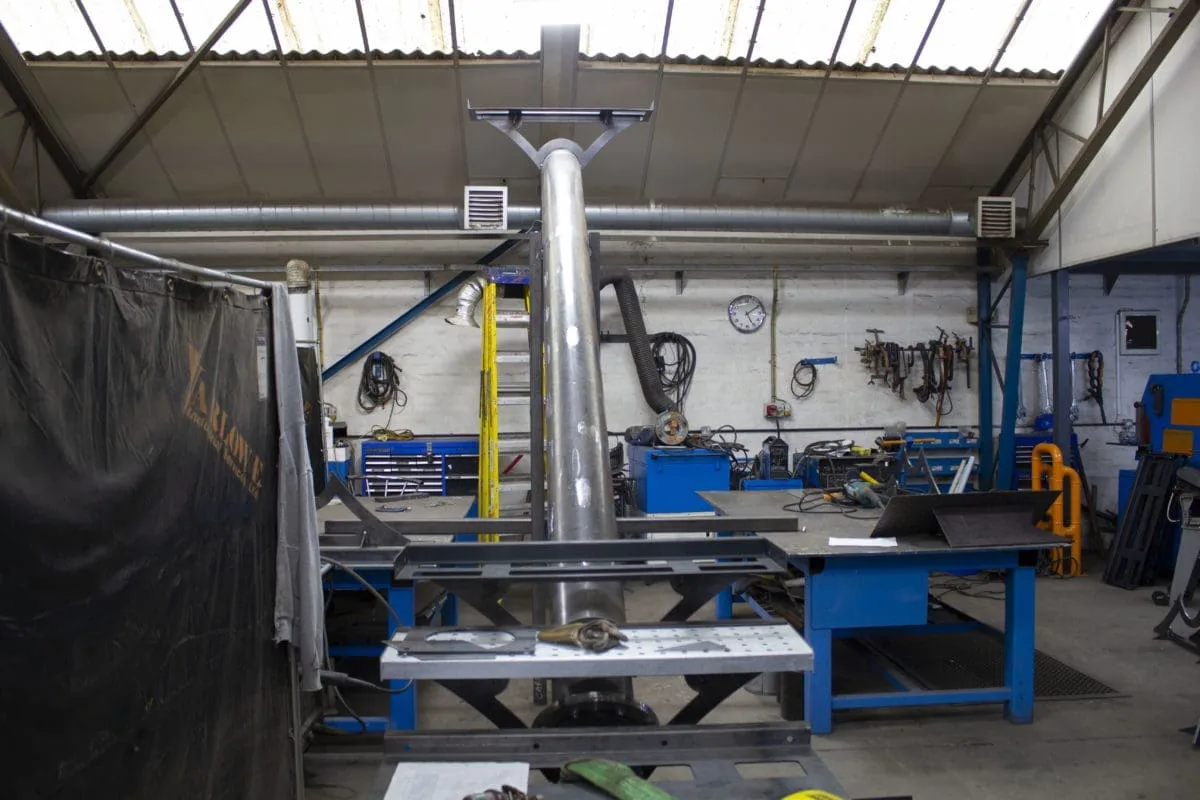

The project involved fabricating and installing pipework ranging from 150mm to 300mm in diameter, integrating a solenoid and customised bracketry.

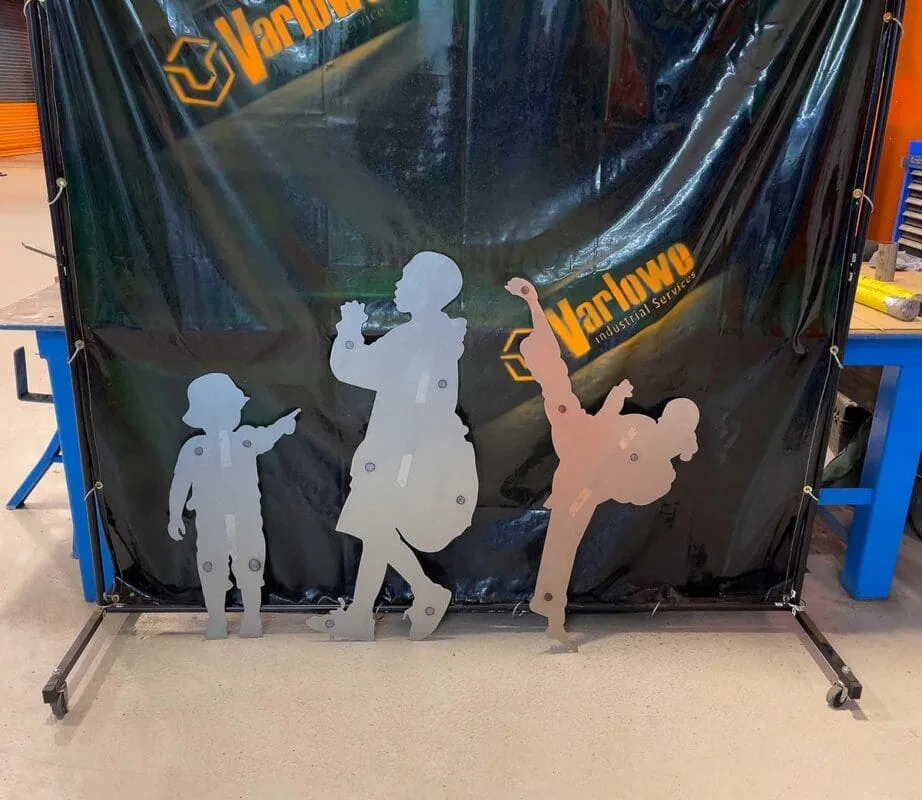

Varlowe’s highly skilled welding and pipework engineers fabricated the stainless steel pipework and bracketry at their workshop. They were then delivered to the site and handed over to the site team for installation. They also tested and purged the new gas main in compliance with IGEM/UP/2 standards to guarantee the quality of the installation.

The project was completed on time and within budget, exceeding the client’s expectations.

Varlowe is committed to delivering exceptional service and results for their clients, handling all aspects of the project with the utmost care and attention to detail, from the design and fabrication of the pipework to the installation and testing process.

Project Details

Project:

Heating Plant Room Installation

Services Required:

Pipe Fabrication, Gas Services, Coded Welding, Repair, Installation, Project Management

Customer:

Briggs And Forrester

NHS QE Hospital

Website:

https://briggsandforrester.co.uk/