Project Description

TJM Projects has been a specialist in interiors and construction services for over 15 years. Their family of skilled designers, crafts-people, project managers and quantity surveyors contribute to the delivery of projects.

They contacted Varlowe Industrial Services to provide a boiler replacement in the plant room of one of their clients’ buildings. The project was under tight time constraints, so we got to work after an initial site survey.

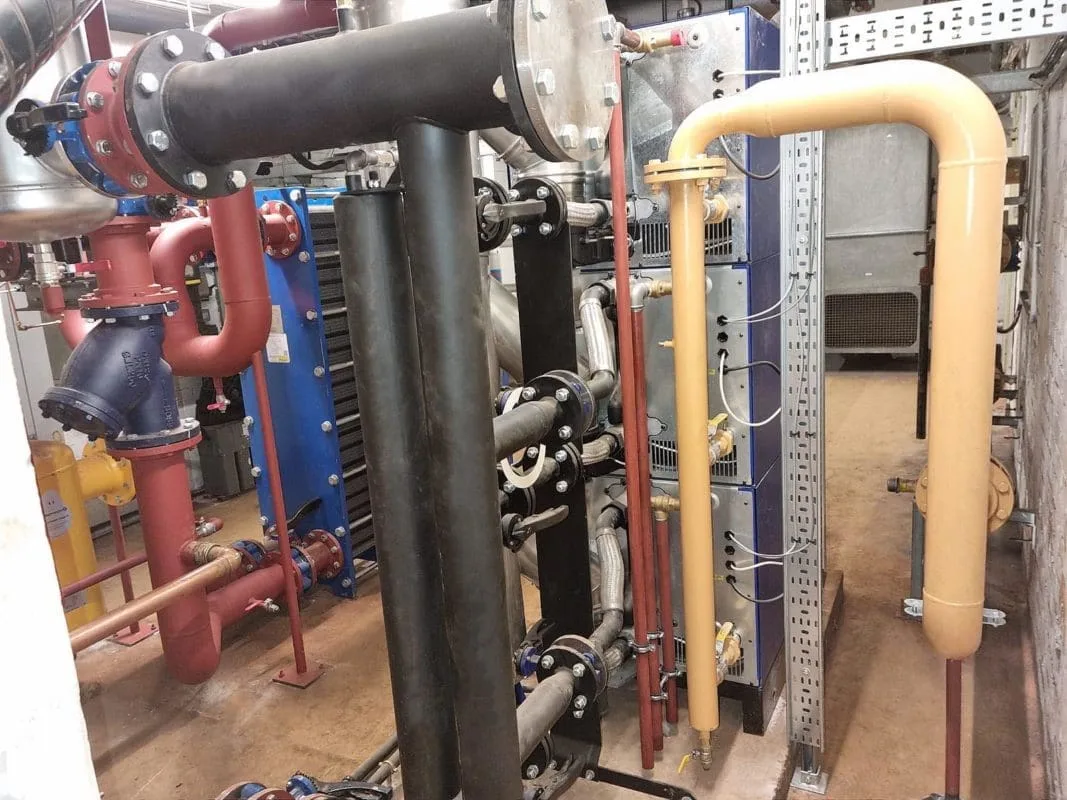

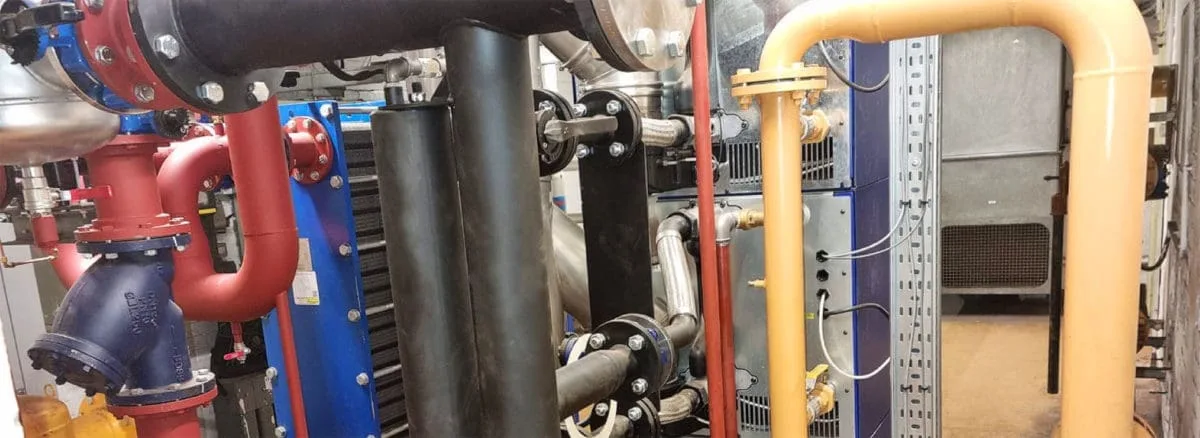

A new 125mm flow and return heating circuit was installed for the new boiler. We also installed a new section of 150mm and 65mm gas carcass.

Once our engineers completed the install of the new low loss header boiler, it was connected to the new pipework.

Also, as part of the scope, we installed new dirt strainers, air separators and a dosing pot which will prolong the life of the new boilers.

The new pipework was sat on bespoke bracketry, which was all fabricated by Varlowe. All pipework was welded in position by our Class 1 Coded engineers, then tested, purged and certified.

On completion, the system was filled, tested and commissioned.

Project Details

Project:

Boiler Replacement

Services Required:

Pipe Fabrication, Gas Services, Coded Welding, Repair, Installation, Project Management

Customer:

TJM Projects

Website:

https://www.tjmprojects.co.uk/